Seica at Productronica: A Powerhouse of Smart Innovation, High Performance and Integrated Solutions.

Active engagement with customers to understand their needs and challenges, together with the deep expertise acquired through decades of experience in developing the test solutions to meet them, has made Seica a powerhouse of smart innovation, able to provide leading-edge, high performance, integrated test solutions. Visitors to Booth A1-538 at Productronica 2025 in Munich will be able to view Seica’s latest solutions dedicated to testing electronic boards, modules and semiconductors and, since automation has become a key factor in optimizing today’s manufacturing processes, Seica’s advanced process automation capabilities will be featured at the show, officially kicking off the celebrations for its upcoming 40th anniversary, which will take place in 2026.

SEICA’s premier flying probe test solution, the PILOT VX, will be on display with a revamped, modern design platform, with unique options like the FlyPod and FlyStrain™ and the optimized VIVA software management, is the gold standard in terms of flying probe speed and performance and is a tremendously powerful asset, deployable in every phase of today’s accelerated product lifecycle, from concept, to design, to prototype, to production.

The PILOT VX is fully automated and its state-of-the-art mechanical architecture and proprietary motion controllers enable reduction of up to 50% in test time. 12 multi-function test heads provide the capability for double-side probing of up to 60 points simultaneously and a technologically advanced measurement hardware, with the capability to power the board (up to 2A per probe) via all of the 8 standard electrical probes, and a new microwave-based measurement technique provide unrivaled test performance.

This is combined with a next generation of LED sensors combining visible and infrared sensors in a single all-in-one unit, or a 750+ MHz flying oscilloscope to break new limits in high frequency applications. The VIVA™ software platform saves even more time by enabling the parallelization of different types of tests, and smart analysis capabilities based on the principles of artificial intelligence can automatically optimize the test flow in run-time.

Visitors will also see two new solutions, the latest additions to Seica’s VALID PLATFORM, renowned for high-performance in-circuit and functional test via a bed-of-nails or fixed, industry-standard receiver.

The VALID SL will be on display in a fully automated PCBA production line, with Seica Automation loading/unloading modules, label applicator, and conveyors. The design allows for easy integration into high-volume production environments, offering flexibility, cost savings, and increased productivity. Its cableless architecture ensures optimum integrity and reliability as well as long-term maintenance, and it is equipped with new 128-channel scanner cards, enabling configurations of over 4,400 channels, ideal for the most complex test requirements. The expanded standard test area can be configured as a single-stage or dual-stage system, and its multi-job architecture, supported by the new version of VIVA™ software, which includes a new operator interface, improves usability for both programmers and operators. Easy access to the system’s internal hardware modules ensures excellent ergonomics making maintenance operations simple and efficient.

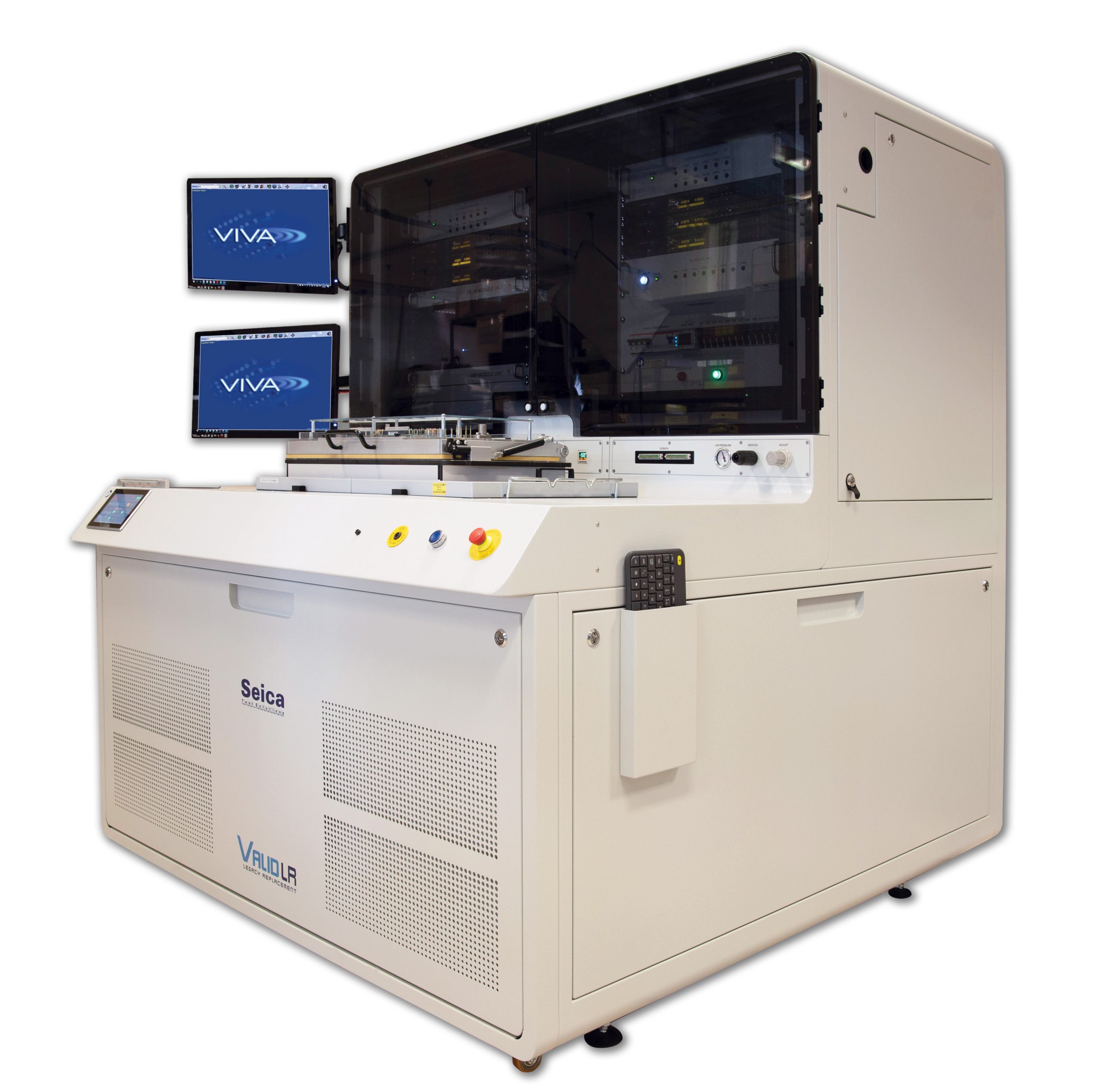

The VALID LR on display is the latest generation Seica’s platform for designed to include the capabilities needed to replace obsolete legacy systems, allowing customers to ensure continuity of established test processes by providing full test program compatibility. Seica has an unparalleled experience in providing legacy replacement solutions, with a consolidated success in replacing numerous brands of legacy test systems, enabling customers to maintain long-term logistics support at competitive costs.

The native multi-resource architecture of the Valid LR gives it the flexibility and performance required for the seamless migration of existing test programs and fixtures, combining the capability to support older technologies with high performance, state-of-the-art tools, which are then also available for the development of new test programs. The VALID LR is engineered for high scalability and performance, with an innovative, cableless architecture, supporting up to 5888 channels with a 1:8 digital multiplexer. It offers up to 24 programmable power supplies, ensuring flexible management of power-on tests. The intuitive, customizable operator interface is built on a PLC system with OPC-UA communication for seamless integration into modern test environments.

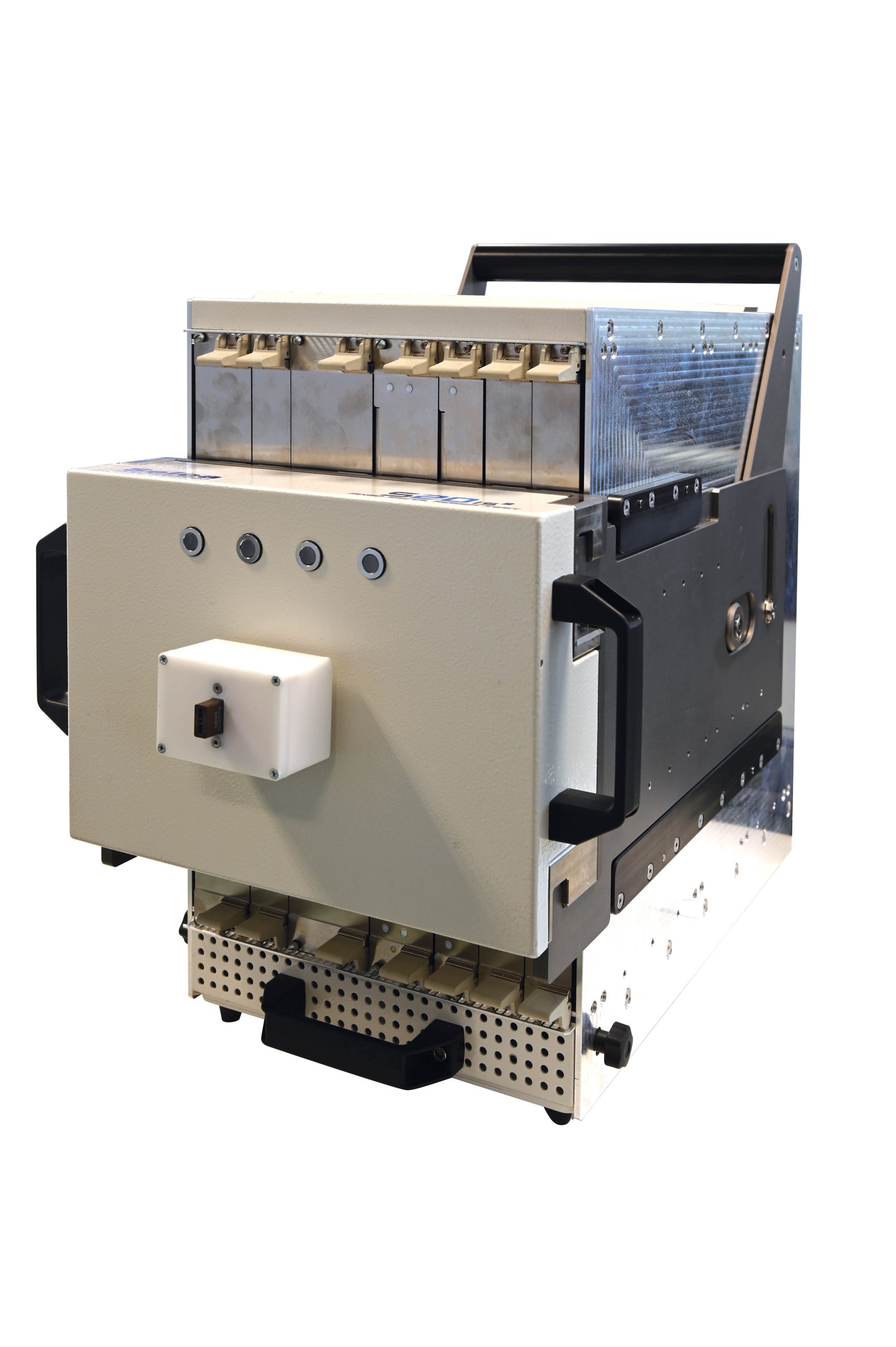

The New S20 line on display includes two solutions dedicated to the testing of power semiconductors. The S20 IS³ offers a cutting-edge solution for testing discrete power devices, including SiC and GaN technologies. Designed for both AC and DC static and dynamic testing, it performs the accurate and repeatable characterization of electrical parameters, a crucial process to ensure the reliability and performance of components such as IGBTs, MOSFETs, and diodes, making it an essential tool for R&D, production, and quality control. Static tests measure key parameters such as on-state voltage (Vce, Vds), leakage current (Ic, Id), and threshold voltage (Vth), ensuring the device meets its electrical specifications, while dynamic tests evaluate switching characteristics, including turn-on/off times, rise/fall times, and energy losses, which are critical for real-world applications. By testing both static and dynamic parameters, manufacturers can detect potential failures before the components are integrated into power systems, thereby avoiding costly field failures while certifying that devices will perform optimally under operating conditions.

S20 IS³ has a compact, space-saving design, with one-box integration of DC-Static, Gate, AC-Dynamic testing. The system is configurable, so the user can include the modules to perform the tests you need today, and expandable, allowing more modules to be added to meet new test requirements. The integrated high-level, menu-driven software is user-friendly, making for easy test setup, and a series of features, such as the integrated oscilloscope, facilitate the debug process, and provide full traceability of the test results.

The S20 RTH test system is designed to deliver precise thermal resistance (RTH) characterization with advanced power and cooling management capabilities. In modern power supply design, increased attention is given to the electrical efficiency of the overall system and to the junction temperature of semiconductor devices, and this kind of test evaluates the thermal stress on power MOSFET devices when they are used in switch mode power supplies. By this computation and with the physical characteristics of the device, it is possible to predict the temperature reached inside the junction, and the allowable margin or heatsink required to assure that the system has a suitable thermal margin during operation. This approach is fundamental because correct computation allows for a more accurate evaluation of component/device lifetime and assures working operation within the Safe Operating Area.

Seica’s power switching hardware is a key element of the test architecture, enabling a programmable controlled shutdown of the load current which minimizes oscillations, allowing the system to perform precise measurements as soon as 80µs after the high current shutdown. The configuration of the bench is scalable, starting from 2 Devices Under Test (DUTs) up to 12 DUTs tested in parallel, depending on throughput needs. The temperature, flow and pressure of the coolant to each DUT is automatically measured and controlled by the system, optimizing thermal stability and ensuring reliable measurements. Purging cooling liquids is handled by the system either into a stand-alone reservoir or into your plant wide system. This feature greatly simplifies initial setup operations, and can handle temperatures of up to 120°C and flow rates up to 100 l/min.