Seica Israel, together with Spider Engineering – Seica’s long-standing local partner – is excited to announce its participation in the New-Tech 2025 Exhibition, Israel’s largest and most influential event for the electronics and high-tech industries. Taking place on May 20–21 at EXPO Tel Aviv, Pavilion 1, this premier trade show brings together more than 150 companies from around the world and draws thousands of professionals from the electronics, manufacturing, and R&D sectors.

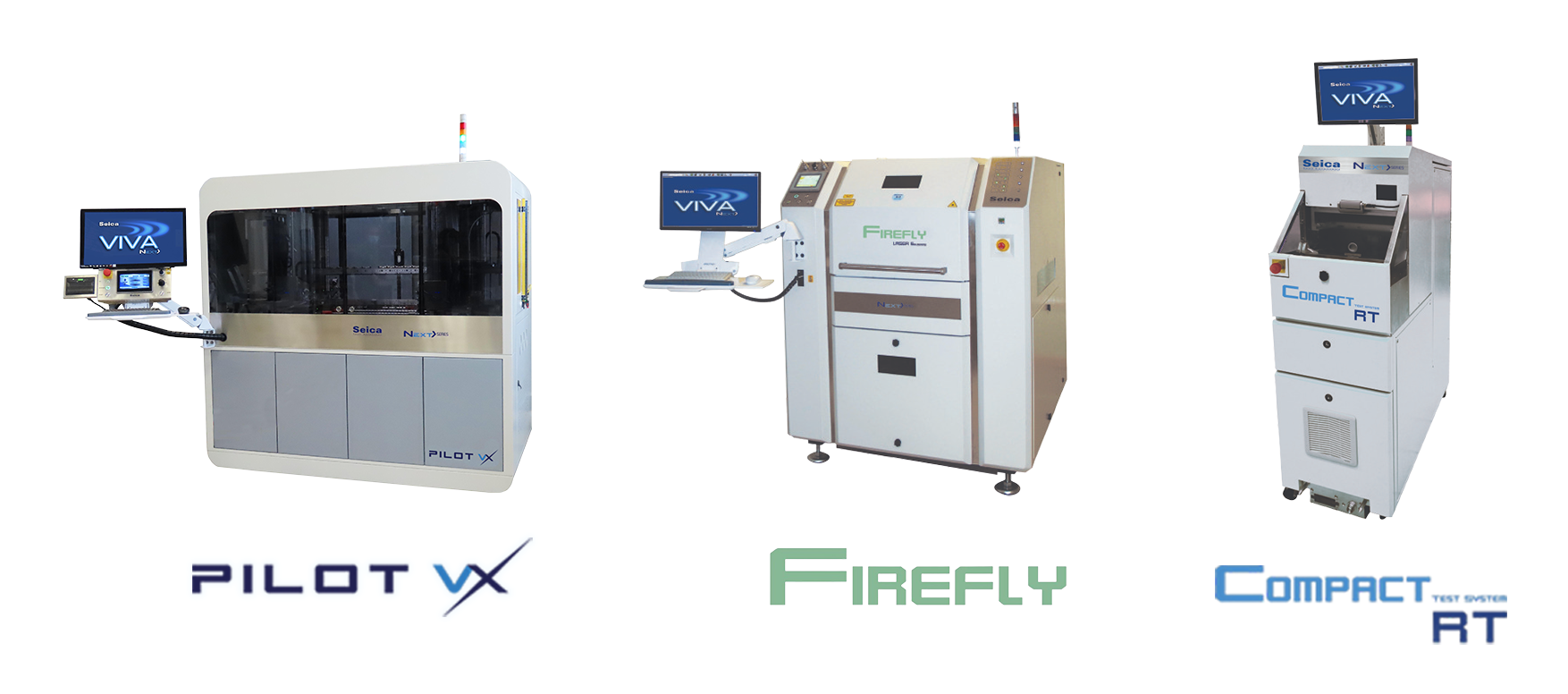

At Booth 83, Seica and Spider Engineering will present a range of cutting-edge solutions for electronic testing and manufacturing, including the Pilot VX, Firefly, and Compact RT systems.

The Pilot VX is Seica’s most advanced flying probe tester, offering exceptional speed and precision. Built on a next-generation mechanical platform with sophisticated motion control, it can reduce test times by up to 50%. With 12 multifunction test heads, the system can probe up to 44 points simultaneously on both sides of the board. It incorporates innovative microwave-based measurement technology and runs on Seica’s VIVA software platform, which uses AI-driven analysis to dynamically optimize the test flow. Options such as FlyPod—enabling up to 14 channels for onboard programming without external cabling—and FlyStrain™, which generates pressure/force maps, make the Pilot VX a powerful solution from prototyping to full-scale production.

Also showcased at Booth 83 is the Firefly, Seica’s laser selective soldering system, engineered for maximum precision, efficiency, and sustainability. Featuring a high-performance laser source, closed-loop feedback, and a programmable donut-shaped beam, the Firefly ensures repeatable, high-quality solder joints—even on the smallest pads. It supports both top and bottom soldering, integrates seamlessly into high-volume production lines, and operates without nitrogen, waste, or high energy consumption. Clean, low-maintenance, and highly flexible, the Firefly is perfectly suited for today’s EMS and OEM manufacturing environments.

Completing the lineup is the Compact RT, a fully automated rotary-table testing system designed for medium- to high-volume production. Its architecture allows one unit under test (UUT) to be loaded while another is being tested, significantly boosting throughput. The system supports both robotic and manual operation and features full integration with the VIVA platform and Seica’s ACL measurement module, enabling a combination of in-circuit and functional testing. Additional highlights include built-in RFID for fixture recognition and test program management, as well as compact, easily swappable adapters with Pylon™ connectors—ensuring fast setup, reliable contact, and reduced storage costs.

All of the solutions on display feature Seica’s VIVA software platform, which provides intelligent integration with every aspect of the customer’s manufacturing process—including data collection, traceability, MES interaction, and repair operations.

Additionally, each system is equipped with Canavisia’s industrial monitoring solution for remote tracking of current and voltage consumption, mains supply, temperature, light indicators, and other key parameters. These capabilities ensure correct system operation, support predictive maintenance, and align with the latest Industry 5.0 standards.

Join Seica Israel and Spider Engineering at Booth 83 to see how our Innovation can help accelerate yours!